Have you ever wondered how a scientific idea becomes the medicine you take to save your life? Being a scientist is about more than just being in the lab; it requires teamwork, attention to detail, and a genuine interest in science. The unsung Active Pharmaceutical Ingredients (APIs) are at the centre of this process, making medicines useful.

We’ll now take a closer look at how API companies use raw materials to create key components for healthcare and why what they do is more important than some think.

Understanding Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (API) are the core components of any drug. Think of them asa car’s engine: without them, the vehicle won’t move. APIs are biologically active substances that treat symptoms, cure diseases, or manage chronic conditions. For instance, the API relieves your headache— in a painkiller, the rest is just filler.

But here’s the catch: not all APIs are created equal. Quality, purity, and consistency have a direct impact on a drug’s safety and efficacy. This is where active pharmaceutical ingredient manufacturers step in. They’re responsible for producing APIs that meet stringent global standards, ensuring every tablet or injection delivers the intended effect.

Why does this matter to you? Well, when you pop a pill, you’re trusting not just your doctor, but also the API manufacturer behind the scenes. Their expertise ensures that what’s on the label is exactly what’s in the bottle—no compromises.

The Process for API Manufacturing: From Raw Materials to Final Product

Creating APIs isn’t as simple as mixing chemicals in a lab. It’s a meticulous, multi-stage process transforming API raw materials into high-purity ingredients. Here’s a simplified breakdown:

- Sourcing Raw Materials: It starts with procuring high-quality starting materials. API suppliers are critical, ensuring solvents, catalysts, and other inputs meet purity benchmarks.

- Synthesis: Through chemical or biological processes, raw materials are converted into the desired API. This phase demands precision—temperature, pressure, and timing must be flawless.

- Purification: Impurities are removed to meet pharmacopeial standards (USP or IP guidelines). Even a 0.1% deviation can render a batch unusable.

- Quality Control: Rigorous testing ensures the final API is safe, potent, and consistent.

Pharmaceutical ingredients manufacturers like Bulat Pharmaceutical leverage cutting-edge technology to streamline this process while adhering to sustainability goals. After all, efficiency isn’t just about speed—it’s about minimising waste and maximising resource use.

Regulatory Standards and Compliance in API Production

Imagine a world where every API manufacturer operated without rules. Scary, right? Regulatory agencies like the FDA, WHO, and India’s CDSCO enforce strict guidelines to keep patients safe.

Active pharmaceutical ingredient companies must comply with Good Manufacturing Practices (GMP), which cover everything from facility hygiene to staff training. These standards aren’t optional—they’re the bedrock of trust in the pharma industry. For example, GMP ensures:

| Requirement | Purpose |

| Contamination control | Prevents unsafe impurities |

| Documentation | Ensures traceability of every batch |

| Equipment calibration | Guarantees consistent product quality |

Non-compliance isn’t just a legal risk—it’s a reputational disaster. This is why leading API suppliers invest heavily in audits, certifications, and continuous staff training.

Challenges Faced by API Manufacturers

Even the best pharmaceutical ingredients manufacturers face hurdles. For starters, APIs are costly to produce. High-quality api raw material, advanced equipment, and skilled labour aren’t cheap. Then there’s the pressure to slash costs without compromising quality—a tightrope walk in an industry with razor-thin margins.

Environmental regulations add another layer of complexity. Waste disposal, energy consumption, and carbon footprints are under global scrutiny. How do active pharma ingredients stay affordable while going green? Innovation. Companies like Bulat Pharmaceutical are adopting green chemistry and renewable energy to cut emissions and costs simultaneously.

Let’s not forget competition. With India being a global hub for API manufacturers, standing out requires more than just pricing—it demands reliability, scalability, and agility.

The Role of API Manufacturers in Global Drug Development

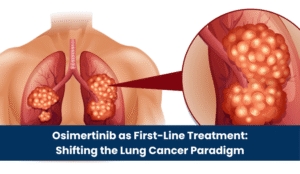

Without APIs, drug development grinds to a halt. Active pharmaceutical ingredient companies partner with pharma firms to turn research into reality. Whether APIs are the common thread, whether a groundbreaking cancer drug or a generic antibiotic, APIsider India’s role is as the “pharmacy of the world.” The country supplies over 20% of global generic medicines, thanks to its robust network of API suppliers. By producing affordable, high-quality APIs, manufacturers ensure life-saving drugs reach the low-income population without the wait.

But it’s not just about volume. API manufacturers enable flexibility. Need to scale up production during a pandemic? Or tweak a formulation for pediatric use? They’re the silent partners making it happen.

How API Manufacturers Drive Pharmaceutical Innovation

Innovation in pharma isn’t limited to new molecules. Sometimes, it’s about improving how APIs are made. For instance, continuous manufacturing—a method championed by forward-thinking active pharmaceutical ingredient manufacturers—reduces production time from weeks to days.

Then there’s bioavailability enhancement. By modifying the structure of an API, manufacturers can boost how well the body absorbs it. This means lower doses, fewer side effects, and better patient outcomes.

Have you heard of peptide APIs? These complex molecules are revolutionising treatments for diabetes and obesity. Producing them requires the expertise of a few pharmaceutical ingredient manufacturers, yet these niche skills push the industry forward.

Sustainability and Ethical Practices in API Manufacturing

Can APIs be made without harming the planet? A simple answer is yes, but it takes commitment. Leading active pharmaceutical ingredient companies are adopting circular economy principles, recycling solvents, and converting waste into energy.

Ethical sourcing is equally critical. Conflict minerals, exploitative labour, and environmentally damaging api raw material extraction have no place in modern pharma. Transparency in supply chains isn’t just a buzzword—it’s a moral obligation.

Bulat Pharmaceutical integrates sustainability into every step. They prove that ethical practices and profitability coexist, from solar-powered facilities to zero-liquid discharge systems.

Bulat Pharmaceutical: Pioneering a Trusted Future in API Manufacturing

Next time you take a pill, remember the journey it’s been on. Active Pharmaceutical Ingredients (API) are the invisible force behind modern medicine, and the API manufacturers producing them are the backbone of global healthcare. They balance science, regulation, and ethics every day.

Companies like Bulat Pharmaceutical stand out in a rapidly evolving industry by marrying innovation with integrity. Whether you’re a healthcare provider or a patient, their commitment to quality ensures you get more than just a drug—you’re getting trust in a tablet.

So, what’s the future of APIs? Smarter processes, greener practices, and therapies we can’t yet imagine. And with active pharmaceutical ingredient companies leading the charge, that future looks brighter.